Welcome, space enthusiasts, to the first installment of our WARR Exploration Journey series, where we delve deeper into our mission’s progress and the exciting discoveries we’re making on our journey through the cosmos. We extend our gratitude to our sponsors, whose generous and continuous support propels our work forward. Let’s embark on this fascinating exploration of our projects!

Project REBELS

Electronics Team: Revving Up with an ESC Prototype

Our team hit a significant milestone with the successful creation of an Electronic Speed Controller (ESC) prototype. This is the driving force behind the wheels of our rover.

The ESC prototype integrates a microcontroller from the STM32L4 family, courtesy of STMicroelectronics, to facilitate communication. A board based on the TMC4671 BLDC driver from Trinamic empowers motor control, and the EPC9146 motor drive board from EPC delivers power stage functions. To ensure Debug and Encoder connections, we used ribbon cables and connectors from Würth Elektronik.

Safety is a top priority for us. The prototype features a galvanic isolation safety measure that safeguards logic components from potential electrical faults on the motor side, enhancing system safety and reliability.

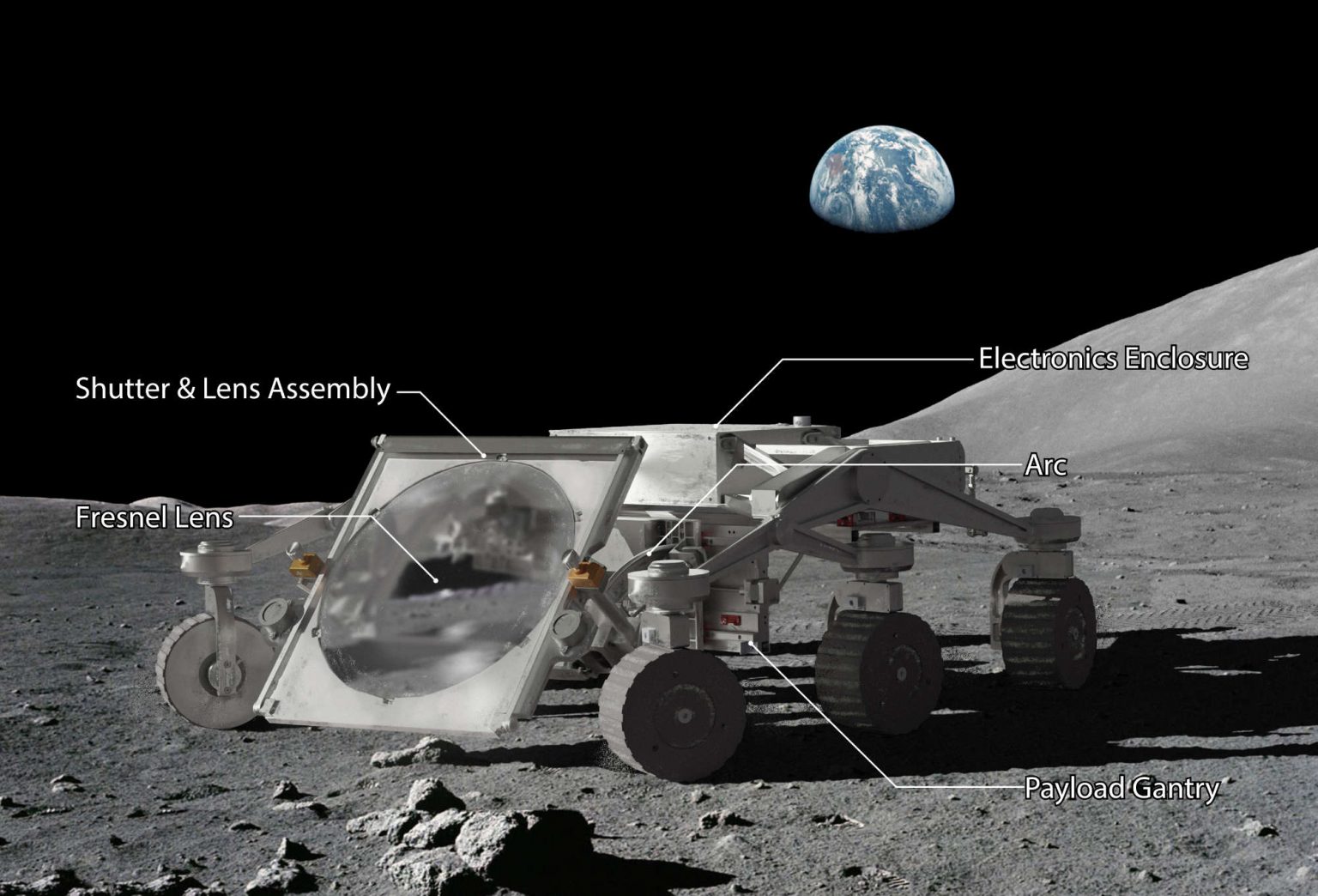

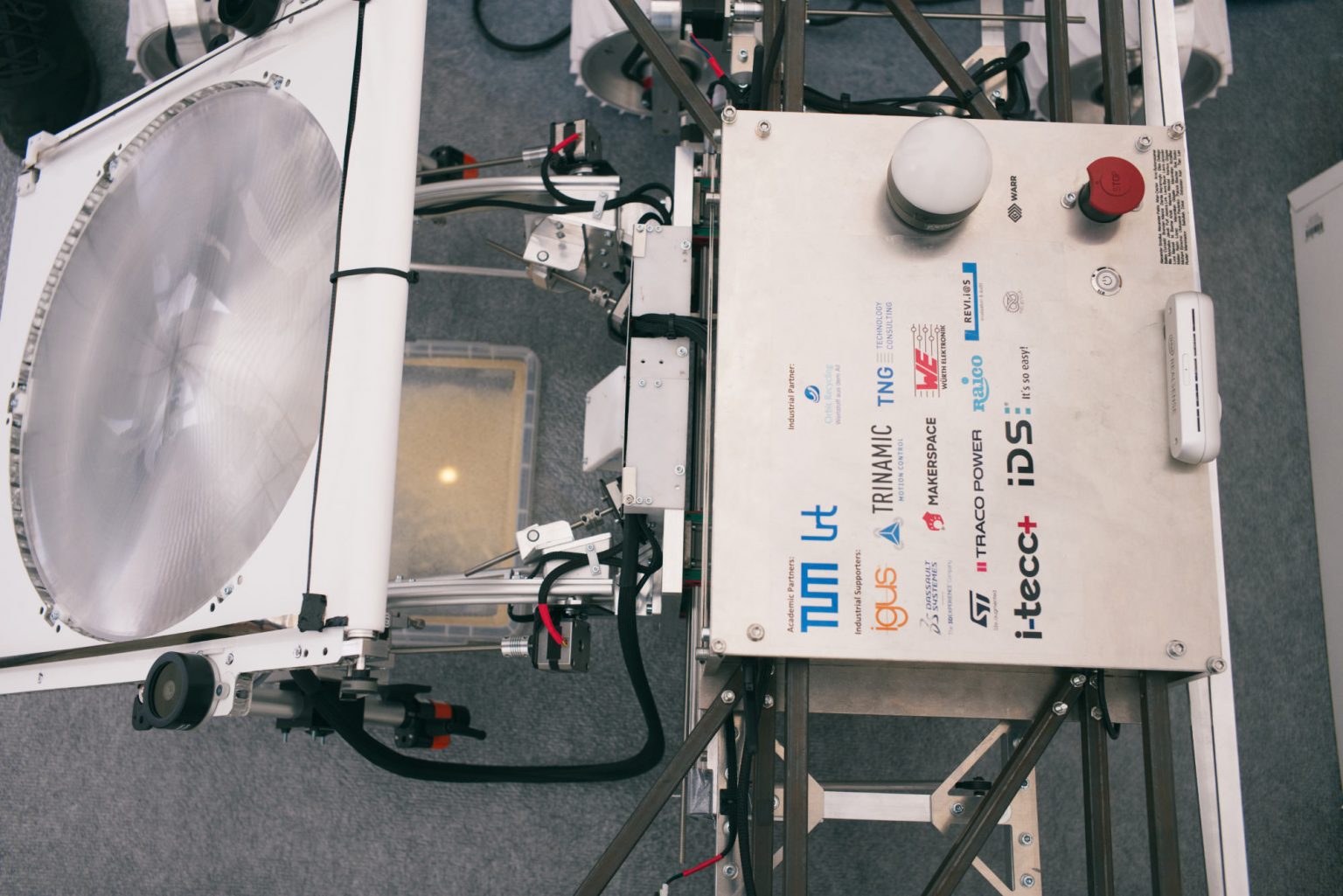

Payload Team: Gearing Up and Sintering On

Our Payload subteam has been hard at work, wrapping up the implementation of mechanical fixes and kicking off a sintering campaign. We’re thrilled to announce that the vertical axis is now fully functional, with spot size adjustment capabilities provided by our dedicated software team.

Kindly supplied by our sponsor igus, the new axis incorporates several parts including the lead screw, rails, carriages, and bearings. The azimuth axis, which we previously improved, now works flawlessly when controlled by sun-tracking software. This has proven invaluable in our sintering campaign, and we’ve already conducted successful experiments with regolith simulant.

Propulsion and Chassis Team: Precision in Progress

The Propulsion and Chassis (PC) team has been making great strides in the MakerSpace. They’ve been meticulously working with the Computer Numerical Control (CNC) mill to manufacture the outer housing for a subassembly known as the “Vertical Joint”, a key component of our rover that allows individual steering of each wheel.

This intricate piece is the most complex part we’ve manufactured ourselves, marking a significant achievement in our project. Our thanks go out to the MakerSpace for providing us with the advanced machinery necessary for this achievement.

Looking Ahead: Project CRATER

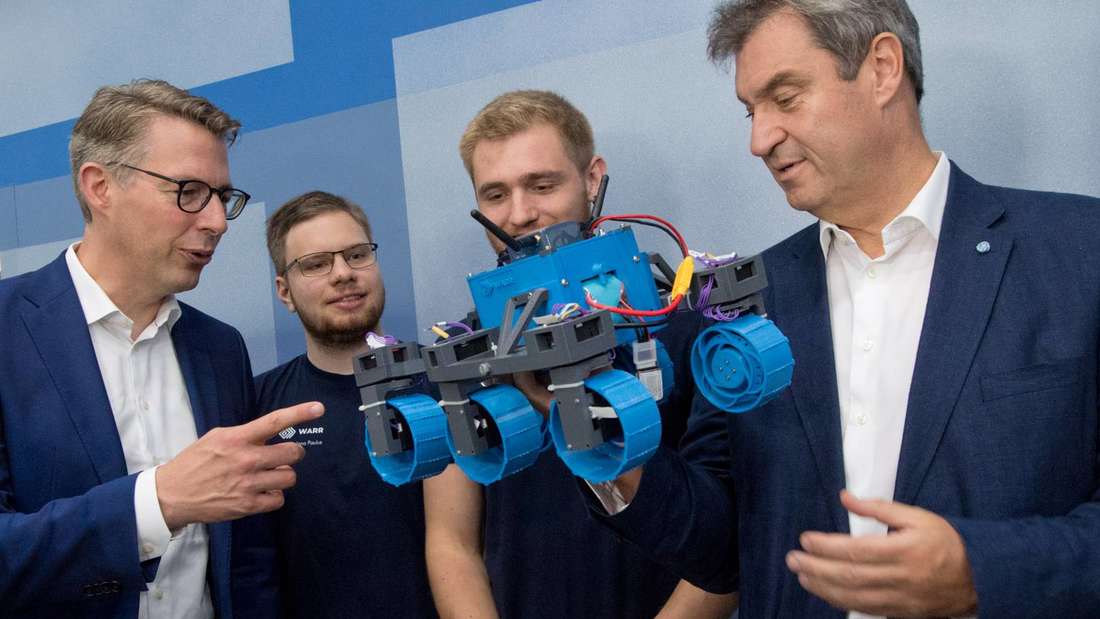

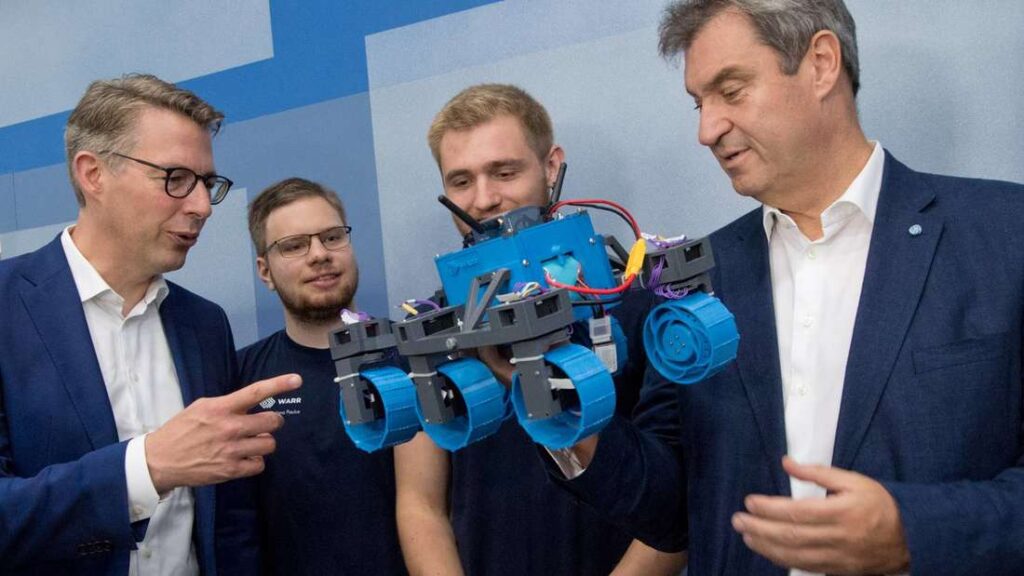

We’re thrilled to introduce Project CRATER: a Compact Rover designed for Autonomous Traversal, Experimentation, and Retrieval on simulated Martian terrain. Packed with state-of-the-art computer vision and odometry, CRATER will navigate its environment, identify targets, and drive towards them, minimizing interactions with obstacles. Once it reaches its destination, its advanced scientific instruments will conduct various experiments on the harsh Martian terrain.

At a recent TUM visit, Markus Söder got a sneak peek of our first prototype! Dubbed the ExoWARR, this Prototype bases its design on the ExoMy: an open-source 3D printed rover developed by the European Space Agency.

Stay tuned for more updates and in-depth explorations in our future blog posts!